Why Direct Drive Motors Are the Game Changer Your Build Needs

- chrish960

- Aug 16

- 3 min read

Hey Kinemaniacs! Let's talk about one of the biggest decisions you'll make in your motion platform journey: direct drive vs. everything else. Spoiler alert—once you experience direct drive, there's no going back.

The "Aha" Moment: What Direct Drive Actually Means

Picture this: you're finally dialing in that perfect sim racing setup, but every time you hit the brakes, there's this tiny delay, this slight "mushiness" that kills the immersion. Or you're working on a VR project and the motion just feels... off. That's mechanical transmission robbing you of precision.

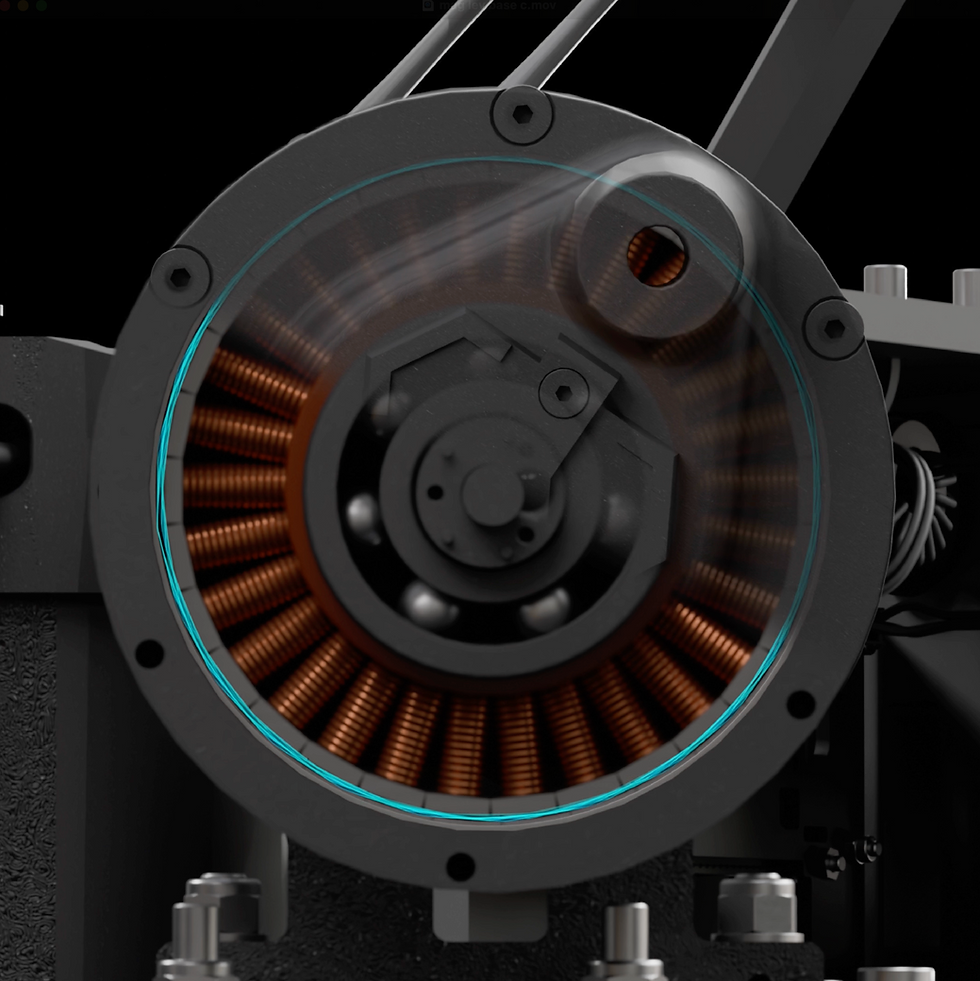

Direct drive changes everything. No gears. No belts. No BS. Just your motor directly connected to what you want to move. It's like the difference between playing a game with input lag versus butter-smooth responsiveness.

The Problems We've All Lived With (Until Now)

Traditional motion systems are basically engineering compromises wrapped in hope:

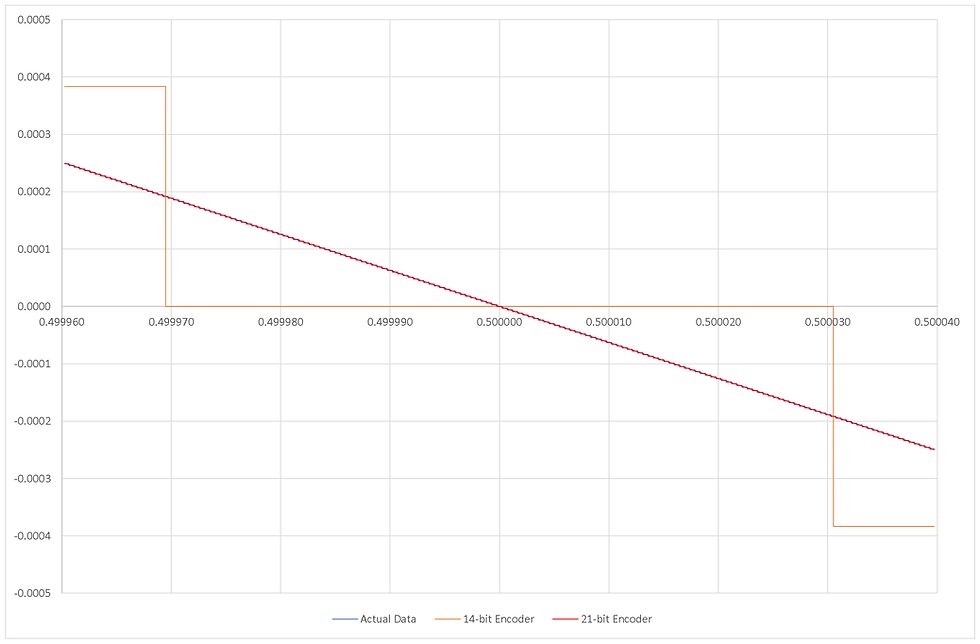

Backlash: That annoying play in gears that means your control inputs get "lost" in mechanical slop Friction: Energy-wasting resistance that fights every movement you're trying to create Wear and Tear: Belts stretch, gears wear, and your precision slowly degrades with every hour of use Noise: Ever tried to enjoy a VR session with a gearbox grinding away next to your head?

Why Direct Drive Wins Every Time

Precision That Actually Matters: When your VR world demands micro-movements, direct drive delivers. No mechanical "telephone game" between your controller and the actual motion.

Instant Response: Your control loop runs at 400Hz? Great. Your direct drive motor keeps up. Try that with a belt drive system and watch your beautiful algorithms get murdered by mechanical lag.

Maintenance You Can Actually Handle: Fewer moving parts mean fewer things that break. Your weekend project time goes into building cool stuff, not replacing worn belts.

Whisper Quiet Operation: Your neighbors won't know you're testing 4G forces at 2 AM. Your family won't complain about the "robot noises" from your workshop.

Real Talk: What This Means for Your Projects

For VR Builders: Remember that nauseating disconnect between visual and motion feedback? Direct drive eliminates it. Your vestibular system finally trusts what your eyes are seeing.

For Sim Racing Enthusiasts: Feel the difference between understeer building up gradually versus snapping suddenly. Direct drive captures the subtle force changes that make you genuinely faster on track.

For Makers and Tinkerers: Your custom haptic feedback project, that robotic arm prototype, that art installation that responds to touch—all of these become possible when your mechanical system doesn't fight your algorithms.

For the Research-Minded: Repeatability matters. When your platform responds identically to the same inputs every time, your data actually means something.

The Engineering Beauty of Simplicity

There's something elegant about eliminating the unnecessary. Every gear reduction, every belt, every coupling is a potential failure point and a guaranteed precision killer. Direct drive systems are minimalist engineering at its finest—maximum capability with minimum complexity.

Compact Design Freedom: Without bulky gearboxes eating up space, your platform fits in spaces you never thought possible. That spare bedroom? Now it's a motion lab.

Energy Efficiency: Power goes directly into motion instead of being lost in mechanical friction. Your electricity bill thanks you, and your motors run cooler.

What the Community can Build

What the Community can Build

The projects that become possible with direct drive systems are next-level:

Medical rehabilitation devices with precise, repeatable therapy protocols

Research platforms contributing to published scientific work

Training simulators that universities actually want to purchase

Art installations that respond to the subtlest human interactions

The Future is Direct

As our community pushes the boundaries of what's possible in garage workshops and home labs, direct drive technology gives us the foundation we need. It's not just about smoother motion—it's about unlocking applications that weren't possible before.

Your ideas deserve precision that matches their ambition.

Community Challenge

Drop a comment: What project are you working on that would benefit from direct drive precision? Whether it's eliminating that annoying vibration in your current rig or enabling something completely new, let's brainstorm how direct drive could take your build to the next level.

The age of "good enough" motion control is over. Welcome to the direct drive revolution, Kinemaniacs.

Ready to experience the difference? The PDK's direct drive architecture is waiting to transform your next project. Because when precision matters, compromise isn't an option.